IDENTIFICATION OF PLASTICS:

IDENTIFICATION TECHNIQUES

SIMPLE INSTRUMENTAL

1. APPEARANCE. 1. THERMAL ANALYZER

2. METHOD OF 2. GPC

FABRICATION

3. PENETRATION TO 3. X RAY DIFRACTIOMETER

HOT ROD AND

CUTTING WITH A 4. I. R. SPECTROSCOPY

KNIFE 5. NMR SPECTROSCOPY

4. FLOTATION TEST

5. SCRATCH RESISTANCE

6. COLOUR

7. ODOUR

8. TEAR

9. SOLUBILITY

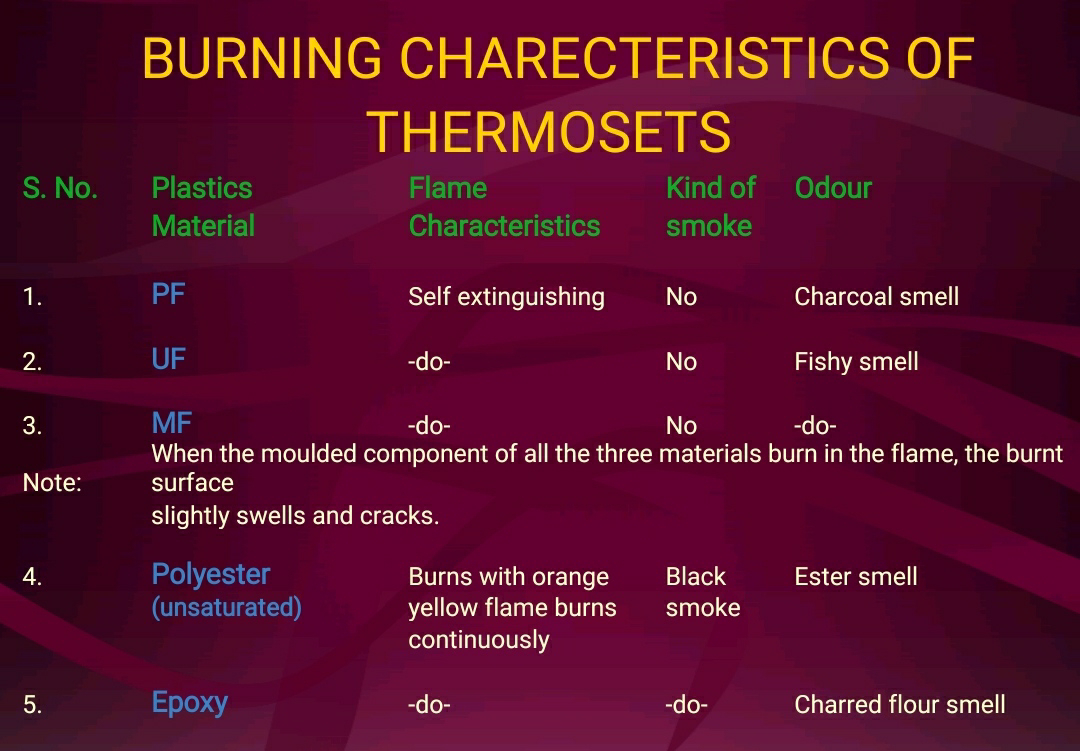

10. BURNING CHARACTERISTICS

11. PYROLYSIS

12. MELTING POINT

13. CONFIRMATION TEST

HOW TO IDENTIFY A PLASTIC ?

Look at the sample. Is it transparent, translucent or opaque?

Feel the sample. Does it bend? Can it be scratched? What does the surface feel like?

Cut the sample with a sharp knife. Does it cut easily: Are the edge smooth or jagged? Does it crumble or flake?

Subject the sample to a float test. Does it float or sink? (the test is invalid if plastic foam. Wash with detergent solution initially to stop air bubbles adhering to surface.)

Try to burn a small piece of sample. What is the size and colour of flame? Is smoke produced? Do molten drips fall from sample and continue to burn? Is the sample self-extinguishing? Is there any odour when flame has been extinguished?

SAFETY: Use only a small sample held with tongs or pliers. Hold sample

BENDING TEST ( WITH MOULDED BAR)

PLASTICS BENDING BEHAVIOUR

1. Polyethylene - Bends, tends to remain

2. Polypropylene - Unbends most of the way

3. Polystyrene - Cracks but retains bend

4. ABS - Bend tends to remain

5. PVC (Rigid) - Bends easily and springs back quickly

6. Cellulose acetate - Bend tends to remain

7. PMMA - Cracks and splinters

8. Nylon - Difficult to bend, springs back

9. Polycarbonate - Tough to bend

THERMOPLASTICS:

VISUAL OBSERVATION TEST

Low gloss easily be scratched by nail - LDPE OR LLDPE High gloss can be scratched by nail - HDPE High gloss cannot be scratched by nail - PP

DROPPING TEST

When a moulded component is dropped on hard surface

Metallic sound Dull sound

PS, HIPS, SAN, ABS Cellulosics Polyamides

PC, PPS PPO

Polysulphone. PTFE,PMMA, Polyacetal, PVC, Polyolefins

TEST TO DIFFERENTIATE:

THERMOPLASTICS AND THERMOSETS

CUTTING TESTS

If a shaving can be pared off with knife, it may be a thermoplastic.

Note:PMMA and Polystyrene are brittle and difficult to pare

If the material is rigid and will not pare off instead flakes of powders, it may probably a thermoset plastic.

HOT ROD PENETRATION TEST

Heat an electronic soldering iron to red hot and press against the unknown sample.

a) If the plastic material softens, and the rod penetrates the sample is thermoplastic.

b) If the plastic material does not soften and the rod does not penetrate, the sample is thermoset plastic.

FLOTATION TEST

When the material is dropped in water

Floats Sinks

Polyolefins. Other than Polyolefins

Note: Filled polyolefins and cellular foams are exceptional for this test.

E.g.Sinks Floats

Talk filled PP PVC , PU

Glass filled PP and PS foams

PYROLYSIS TEST:

HEAT THE SAMPLE IN AN IGNITION TUBE AND TEST THE PYROLYTIC VAPOUR WITH A MOISTENED INDICATOR PAPER.

ACID : TURNS BLUE LITMUS TO RED

BASE : TURNS RED LITMUS TO BLUE.

ACID VAPOURS

MAY COME FROM CARBOHYDRATE POLYMERS & THEIR DERIVATIVES . [E.G., CELLULOSE ACETATE]

HIGH ACID VAPOURS

OFTEN INDICATES THE PRESENCE OF CHLORINE . [E.G., PVC OR RUBBER NEUTRAL VAPORS]

EVOLVED FROM HYDRO CARBON POLYMERS, SILICONES AND SOME POLYESTERS HYDROCHLORIDE.

ALKALINE VAPOURS

INDICATE THE PRESENCE OF N2 . E.G., POLYAMIDE, PUs, PROTEINS & AMINO FORMALDEHYDE RESINS.

No comments:

Post a Comment