5 COMMON GRADES OF PTFE

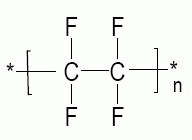

Virgin PTFE

“Virgin PTFE” (PTFE without a filler) is one of the most chemically inert materials known and is used in many different applications and industries.

Glass Filled PTFE

Virgin PTFE with 25% Glass fiber filler which dramatically increases compressive strength and lowers deformation under load.

Bronze Filled PTFE

The addition of Bronze to PTFE gives better dimensional stability and lowers creep, cold flow and wear.

Carbon Filled PTFE

The addition of Carbon Fibre to PTFE increases the compressive strength and wear resistance. It provides good thermal conductivity and low permeability.

Stainless Steel Filled PTFE

The material is extremely hard wearing, has excellent strength and stability under extreme loads and elevated temperatures whilst still retaining the low coefficient of friction of conventional PTFE.

PROCESSING PTFE

Because PTFE is a thermoplastic and due to its high viscosity, it cannot be processed using conventional polymer processing techniques. PTFE is processed by cold shaping and followed by heat treatment (sintering) during which polymer particles fuse to form a solid moulding.

PTFE is highly resistant to corrosion due to its chemical inertness. Unfortunately, that same chemical inertness prevents PTFE from being cross-linked like elastomers and is subject to the phenomenon of cold-flow – otherwise known as “creep”. To reduce and diminish cold-flow, additives are introduced during the preparation of PTFE compounds. Fillers, such as glass fiber found in Durlon 9000 and 9000N gaskets, not only reduce creep but also maintain chemical inertness against aggressive and caustic chemicals but are still considered safe for use by food, drug and medical services.

No comments:

Post a Comment