Chemical Nature of Polymer

1. The molecular weight increases the solubility of the polymer decreases.

2. High molecular weight polymers, on dissolving, yield solutions of high viscosity.

3. Crystalline polymer (due to denser packing of molecular chains) exhibit higher chemical resistance than less crystalline polymers of similar chemical character. Denser packing makes the penetration of solvents (or chemical substance), in the polymeric materials, more difficult.

4. Greater the degree of cross-links in the polymer, lesser is the solubility

Polymer Structure and Morphology

1. In additions to size of the molecules and their distribution, the shapes or structure, of individual polymer molecules also play an important role in determining the properties and process-ability of plastics.

2. Because of the geometry, or morphology, of those molecules some can come closer together than other. These are defined as crystalline, all other are as amorphous.

3. Morphology influences such properties as mechanical and thermal, swelling and solubility, specific gravity and chemical and gravity properties.

4. This behavior of morphology basically occurs with thermoplastics, not thermosetting. When thermosetting are processed, their individual chain segments are strongly together during a chemical reaction that is irreversible.

Crystalline Polymers

1. A small region of a macromolecules materials in which portions of large molecules are linked to each other in some regular way, is called crystalline.

2. Crystallization imparts a denser packing of molecules, thereby increasing the intermolecular forces of attraction.

3. This accounts for a higher and sharper softening point, greater rigidity and strength and greater density. A completely crystalline polymer tends to acquire brittleness.

Amorphous Polymers

1. An amorphous polymers is characterized by completely random arrangement of molecules.

2. While a crystalline region (called crystallites) embedded in amorphous random matrix. Typical crystalline solids are associated with regularly if external form. Polymers with a long repeating unit or with a low degree of symmetry do not crystallize easily and, therefore, generally form amorphous structure e.g. Polystyrene, polyvinyl acetate and polymethyl methacrylate (all are having bulky side groups attached at random to the main carbon chain) are typically amorphous.

Crystalline and Amorphous Polymers

1. Relatively short chains organize themselves into crystalline structures more readily than longer molecules. Therefore, the degree of polymerization (DP) is an important factor in determining the crystallinity of a polymer.

2. Polymers with a high DP have difficulty organizing into layers because they tend to become tangled.

3. As symmetrical molecules approaches within a critical distance, crystal begins to form in the areas where they are most densely packed.

4. A crystallized area is stiffer and stronger, a non-crystalline (amorphous) area together and more flexible.

5. An increasing crystalline in polypropylene increased in creep, heat and stress cracking as well as increased in mould shrinkage.

6. Crystallization tendency decreases by co-polymerization, because it lowers the structural symmetry, so by controlling the extent of co-polymerization, the relative extent of crystallize.

7. The amorphous region can be adjusted to get required hardens, rigidity, heat resistance and flexibility.

8. A crystallize or any amorphous polymer can also be made flexible and plastics by adding plasticizer.

9. The plasticizer neutralization of intermolecular forces of attraction between macromolecules.

The General Morphology of Thermoplastics

The Distinctive Characteristics of Polymers

Performance of Crystalline and Amorphous Polymers

1. Crystalline types of plastics are more difficult to process; requiring more precise control during fabrication, have higher melting temperature and melt viscosities, and tends to shrink and warp more than amorphous types.

2. They have a relatively sharp melting point.

3. That is they do not soften gradually with increasing temperature but remain hard until a given quantity of heat has been absorbed.

4. Heating a crystalline materials above its melting point, then quenching it can produce a polymer that has a far more amorphous. Its properties can be significantly different than if it is cooled properly (slowly) and allowed to re-crystallize, which processing it becomes amorphous.

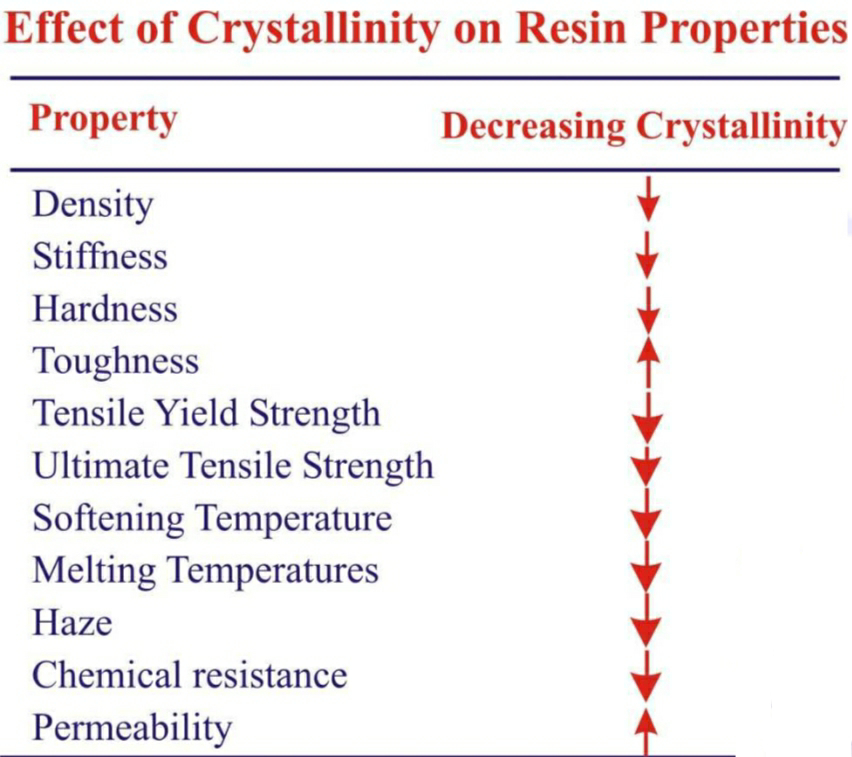

Effect of Crystallization on the properties of polymers

No comments:

Post a Comment